L’énergie de demain, aujourd’hui

NOTRE MISSION

Contribuer à la décarbonation de la mobilité, en fournissant des solutions de recharge facile à déployer, efficientes à exploiter, et alignées avec leur écosystème

NOS SOLUTIONS

NOS PRODUITS ET SERVICES

BORNES DE RECHARGE

KEYWATT® S180

Développée pour répondre à un besoin de charge ultra rapide, sur autoroute ou parkings de centres commerciaux et la charge des poids lourds, notamment en dépôt.

- Conçue pour charger les véhicules légers et les poids lourds

- Déployée sur des parkings privés ou publics

- Haute maintenabilité by design

- Un produit disposant en option du TPE et un DC meter certifié

KEYWATT® S150

Développée pour répondre à un besoin de charge ultra rapide, sur autoroute ou parkings de centres commerciaux et la charge des poids lourds, notamment en dépôt.

- Conçue pour charger les véhicules légers et les poids lourds

- Déployée sur des parkings privés ou publics

- Haute maintenabilité by design

- Un produit disposant en option du TPE et un DC meter certifié

KEYWATT® S120

Développée pour répondre à un besoin de charge ultra rapide, sur autoroute ou parkings de centres commerciaux et la charge des poids lourds, notamment en dépôt.

- Conçue pour charger les véhicules légers et les poids lourds

- Déployée sur des parkings privés ou publics

- Haute maintenabilité by design

- Un produit disposant en option du TPE et un DC meter certifié

KEYWATT® S50

Développée pour répondre à un besoin générique de charge rapide, en voirie, sur autoroute ou sur des parkings privés.

- Déployée sur des parkings privés ou publics

- Refroidissement sans filtre

- Un produit disposant en option du TPE depuis 2022

- Un DC meter certifié pour le marché français dès 2024

KEYWATT® S24

Pensée pour être déployée en voirie et permettre à tous de recharger rapidement, y compris en ville, à coût contenu.

- La référence de la charge DC urbaine en France

- Une borne orientée utilisateur

- Refroidissement sans filtre

- Un produit disposant du TPE depuis 2022

- Un DC meter certifié pour le marché français dès 2024

KEYWATT® W24

Avec son design compact, la KEYWATT® W24 apporte depuis bientôt 10 ans en Europe et en Amérique du Nord la solution la plus facile et la plus économique pour charger rapidement les véhicules électriques.

- Un produit opérationnel depuis bientôt 10 ans

- Déployé en Europe et en Amérique du Nord

- Refroidissement sans filtre

- Propose de multiples combinaisons d’équipement

KEYWATT® W7a

KEYWATT® W7a est la première wallbox AC proposée par IES SYNERGY. Elle devient une composante importante de notre offre destinée à la recharge sur parking privé. Sa prise T2S frontale permet une grande variété d’implantations et une expérience de charge la plus fluide possible.

KEYWATT® B50

Développée exclusivement pour la charge en dépôt des poids lourds électriques, B50 se distingue de ses concurrentes par son empreinte au sol réduite et son système de refroidissement sans filtre.

- Une borne développée pour les dépôts de bus

- Une interface utilisateur simple

- Un modèle compatible avec de nombreux poids lourds

- Refroidissement sans filtre

KEYWATT® C50

Développée pour les constructeurs, leurs laboratoires, leurs usines et centres de réparation. Un produit bénéficiant de nombreuses références partout dans le monde, muni de connecteurs interchangeables et protocole de communication modifiables.

- Chargeur Mobile

- Une grande variété de câbles disponibles, interchangeables

- Adapté aux besoins des constructeurs de VE

- Certifié pour l’Europe et l’Amérique du Nord

SERVICES

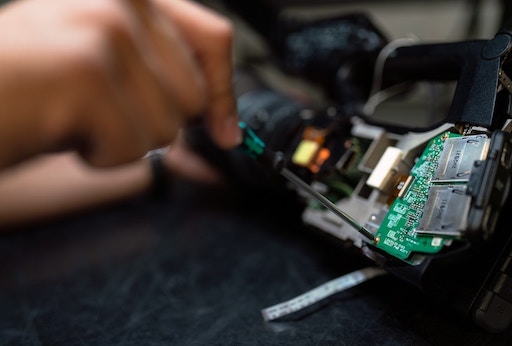

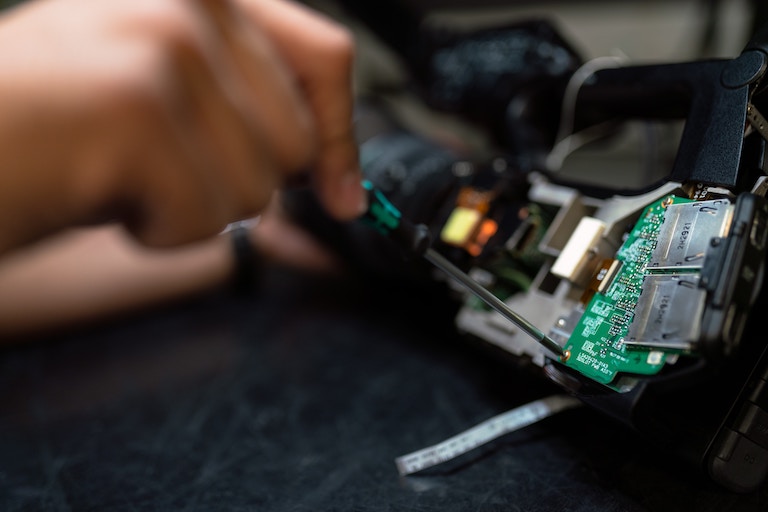

FORMATION

Des formations pour assurer la maintenance des bornes de recharge KEYWATT® au sein de notre centre de formation IES Synergy, en ligne ou sur site

EXPÉRIENCE CLIENTS

Marty

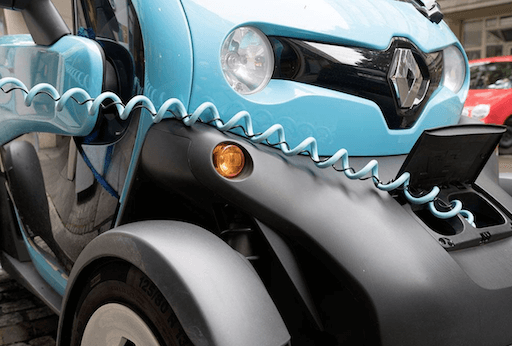

Une collaboration active sur l’interopérabilité entre IES, Marty, Energys et Renault Trucks avec une borne Keywatt S180 pour la recharge des camions.

Green Yellow

La recharge à destination pour nos clients, sous ombrières, rendue possible grâce au bon produit, une station de recharge Keywatt S24 et son double modem.

Jaguar Land Rover

Des bornes Keywatt W24 dans toutes les concessions Jaguar Land Rover d’Italie – un succès car adaptées à chaque localisation (pas besoin d’augmenter la capacité électrique), grâce au wallbox DC, tout en étant compétitif sur le marché !

Brest Métropole

La transformation de la mobilité à Brest Métropole pour les bus électriques du site de Kergonan grâce à la Keywatt S180, avec sa simplicité d’utilisation et son architecture modulaire venus améliorer considérablement l’expérience utilisateur et le service.

Carrefour Market

Superbe collaboration et partenariat entre IES & Driveco en fournissant de multiple Carrefour Market avec les bornes Keywatt S50 et S180 au couleur.

![]()

ACTUALITÉS

L’Engagement d’IES Synergy dans l’Électrification des Transports Lourds

ACTUALITÉSÀ l'aube d'une nouvelle ère de mobilité, la transformation énergétique dans le secteur...

IES Synergy au salon DIE Flotte!

ACTUALITÉSNous nous réjouissons d’avoir des conversations intéressantes avec vous à Düsseldorf...

Bectrol et IES Synergy révolutionnent le chargement des véhicules électriques en Amérique du Nord

ACTUALITÉSNouvelle électrisante : BECTROL & IES Synergy forment une alliance pour électrifier...

c’est :

15 000 +

Bornes installées

1 140 000 +

Chargeurs embarqués

1 300 M

de tonnes de CO2 évitées

A PROPOS D’IES SYNERGY

Les Bornes de Recharge pour véhicules électriques : Catalyseurs de la Mobilité de Demain

Dans un monde où la transition énergétique est plus que jamais à l’ordre du jour, les bornes de recharge pour véhicules électriques (VE) se positionnent comme des éléments clés de cette révolution. Avec une croissance exponentielle du marché des VE, la demande en solutions de recharge fiables et efficaces est en constante augmentation, offrant des perspectives prometteuses pour les acteurs du secteur, à l’instar d’IES Synergy.

IES Synergy, pionnier français dans la fabrication de bornes de recharge, s’inscrit au cœur de cette dynamique. Notre engagement envers la qualité, la fiabilité et l’interopérabilité de nos produits reflète une compréhension profonde des besoins diversifiés des différents segments de clients. Les solutions de recharge proposées par IES Synergy, notamment à travers notre technologie Keywatt, sont conçues pour s’adapter et évoluer avec l’écosystème des VE, offrant ainsi une expérience utilisateur optimale.

L’innovation est au cœur de la stratégie d’IES Synergy. En investissant constamment dans la recherche et le développement, l’entreprise vise à offrir des technologies de recharge de pointe, y compris des solutions de recharge ultra-rapide et même des stations alimentées à l’énergie solaire. Cette approche visionnaire anticipe les évolutions technologiques et s’adapte aux exigences changeantes du marché.

L’adoption de bornes de recharge offre également des opportunités commerciales importantes pour les entreprises. Non seulement elles peuvent améliorer leur image de marque en tant qu’acteurs écoresponsables, mais elles peuvent également générer de nouvelles sources de revenus. Que ce soit pour les entreprises proposant des services de recharge au public ou pour celles offrant des solutions de recharge à leurs employés, les bornes de recharge VE représentent un investissement stratégique pour l’avenir.

Cependant, la mise en œuvre de ces solutions n’est pas exempte de défis. Le coût initial, la gestion de l’énergie et l’intégration dans des environnements complexes sont autant de barrières potentielles. IES Synergy, grâce à son expertise, offre des solutions pratiques pour surmonter ces obstacles, permettant ainsi aux entreprises de toutes tailles de participer activement à la transition vers une mobilité plus durable.

CONTACT & DEVIS